Produktbeschreiwung

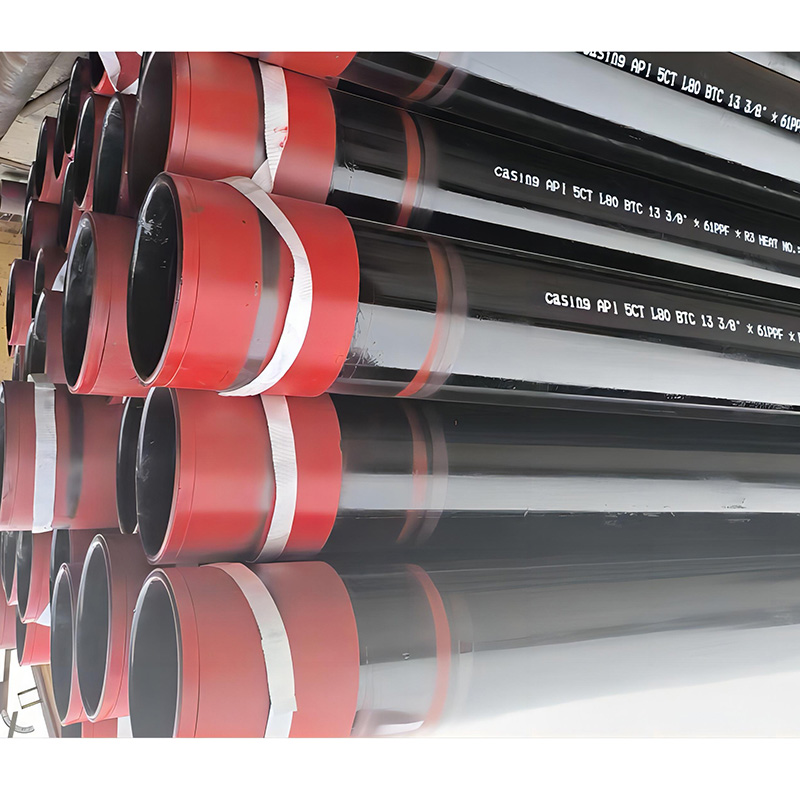

Gehäuse a Réier gi wäit verbreet fir d'Entwécklung vun Ueleg a Gas benotzt. Gehäuse a Réier si wesentlech Komponenten an der Ueleg- a Gasindustrie, déi fir d'Extraktioun an den Transport vu Kuelewaasserstoffer (Ueleg an Äerdgas) aus ënnerierdesche Reservoiren op d'Uewerfläch benotzt ginn. Si spille eng entscheedend Roll fir d'Sécherheet, d'Integritéit an d'Effizienz vun de Buer- an Produktiounsoperatiounen ze garantéieren.

Schlauchleitungen sinn eng Zort Pipeline, déi benotzt gëtt fir Réiueleg an Äerdgas aus der Uelegschicht oder Gasschicht an de Buedem ze transportéieren, nodeems d'Buerungen ofgeschloss sinn. Schlauchleitungen kënnen den Drock entstoen, deen während dem Extraktiounsprozess generéiert gëtt. Schlauchleitungen ginn op déiselwecht Aart a Weis wéi e Mantel hiergestallt, awer de Prozess, deen "Upsetting" genannt gëtt, ass zousätzlech néideg fir d'Schlauchleitung ze verdicken.

E Mantel gëtt benotzt fir d'Buerlächer ze schützen, déi fir Ueleg an de Buedem gegruewe goufen. Genee wéi d'Buerrohr benotzt, erlaben Uelegbuermantelrohren och den axialen Spannungsdrock, sou datt héichwäertege Stol mat héijer Festigkeit gebraucht gëtt. OCTG-Mantelrohren si Päifen mat groussen Duerchmiesser, déi an d'Buerlach zementéiert ginn.

Spezifikatiounen

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9, Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

ISO/API Stolgehäuse Lëscht

| Etikettena | Baussen Duerchmiesser D mm | Nominal linear Massb, c Konditioune kg/m² | Mauer Déckt t mm | Aart vun der Endfinish | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Typ 1,Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9,50 10,50 11,60 13,50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11,50 13.00 Auer 15.00 Auer 18.00 Auer 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 Auer 15,50 17.00 Auer 20.00 Auer 23.00 Auer 26,80 29,70 32,60 35.30 38,00 40,50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 Auer 24.00 Auer 28.00 Auer 32,00 Auer | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 Auer 20.00 Auer 23.00 Auer 26.00 Auer 29.00 Auer 32,00 Auer 35,00 38,00 42,70 46,40 50,10 53,60 57,10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Kuckt d'Notizen um Enn vun der Tabell. | ||||||||||||

| Etikettena | Baussen Duerchmiesser D mm | Nominal linear Massb, c Konditioune kg/m² | Mauer Déckt t mm | Aart vun der Endfinish | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Typ 1,Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 Auer 26.40 29,70 33,70 39,00 42,80 45.30 47.10 51,20 55,30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19.685 | 6.860 | 1.511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 Auer 28.00 Auer 32,00 Auer 36,00 40,00 44,00 49,00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36,00 40,00 43,50 47,00 53,50 58,40 59,40 64,90 70,30 75,60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32,75 40,50 45,50 51,00 55,50 60,70 65,70 73,20 79,20 85,30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42,00 47,00 54,00 60,00 65,00 71,00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48,00 54,50 61,00 68,00 72,00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Kuckt d'Notizen um Enn vun der Tabell. | ||||||||||||

| Etikettena | Baussen Duerchmiesser D mm | Nominal linear Massb, c Konditioune kg/m² | Mauer Déckt t mm | Aart vun der Endfinish | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Typ 1,Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65,00 75,00 84,00 109,00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87,50 | 47.308 | 13.021 | 1.105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94,00 106,50 133,00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Einfache Säit, S = Kuerzen, ronne Gewënn, L = Laangen, ronne Gewënn, B = Buttress-Gewënn, E = Extrem-Line. | ||||||||||||

| ♦ Etiketten sinn als Informatioun an Hëllef bei der Bestellung. ♦ Nominell linear Massen, mat Gewënd a gekoppelt (Kol. 2) ginn nëmme fir Informatiounszwecker gewisen. ♦ D'Dicht vu martensitesche Chromstähle (L80 Typen 9Cr an 13Cr) ënnerscheede sech vun de vu Kuelestähle. Déi ugewise Massen sinn dofir net genee fir martensitesch Chromstähle. E Massekorrekturfaktor vun 0,989 kann benotzt ginn. | ||||||||||||

| Etiketten | Aussenduerchmiesser D mm | Einfach linear Mass kg/m² | Wanddicke t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9,92 11.35 13.05 17,95 19,83 27,66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Lëscht vun ISO/API Stolrohren

| Etiketten | Baussen Duerchmiesser D mm | Nominal linear Massena, b | Mauer déck- heet t mm | Aart vun der Finishc | |||||||||||

| Net- opgeregt Konditioune kg/m² | Ext. opgeregt Konditioune kg/m² | Integrativ. Gelenk kg/m² | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Konditioune | EU Konditioune | IJ | H40 | J55 | L80 | N80 Typ 1,Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2,40 2,75 3,65 4.42 5.15 | — 2,90 3,73 — — | 2,40 2,76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4,50 | — — | 3,25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4,60 5,80 6,60 7,35 | 4,70 5,95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7,80 8,60 9.35 | 6,50 7,90 8,70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10,50 11,50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7,70 9.20 10.20 12,70 14.30 Auer 15,50 17.00 Auer | — 9.30 Auer — 12,95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9,50 10,70 13.20 16.10 18,90 22.20 | — 11.00 Auer — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12,60 15.20 17.00 Auer 18,90 21,50 23,70 26.10 | 12,75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Einfach Enn, N = Net verstäerkt mat Gewinde a gekoppelt, U = Extern verstäerkt mat Gewinde a gekoppelt, I = Integralverbindung. | |||||||||||||||

| ♦ Nominell linear Massen, Gewënn a Kupplung (Kol. 2, 3, 4) sinn nëmme fir Informatiounszwecker ugewisen. ♦ D'Dicht vu martensitesche Chromstähle (L80 Typen 9Cr an 13Cr) ënnerscheede sech vun de vu Kuelestähle. Déi ugewise Massen sinn dofir net genee fir martensitesch Chromstähle. E Massekorrekturfaktor vun 0,989 kann benotzt ginn. ♦ Net-verstuerzt Schläich sinn mat normale Kupplungen oder spezielle Schiefkupplungen verfügbar. Extern verstuerzt Schläich sinn mat normale Kupplungen, spezielle Schiefkupplungen oder spezielle Spaltkupplungen verfügbar. | |||||||||||||||

Standard & Grad

Gehäuse a Réier Standardqualitéiten:

API 5CT J55, K55, L80, N80, P110, C90, T95, H40

API 5CT Gehäuse a Schlauchleitungen:

(STC) Kuerz ronnt Gewënngehäuse

(LC) Laangt ronnt Gewindegehäuse

(BC) Supporter Gewënngehäuse

(XC) Extrem-Line Gehäuse

(NU) Net-verréckelt Schlauch

(EU) Extern verstoppte Schlauch

(IJ) Integralverbindungsschlauch

D'Gehäuse an d'Réier solle geméiss den uewe genannten Verbindungen mam Standard API5CT / API Standards geliwwert ginn.

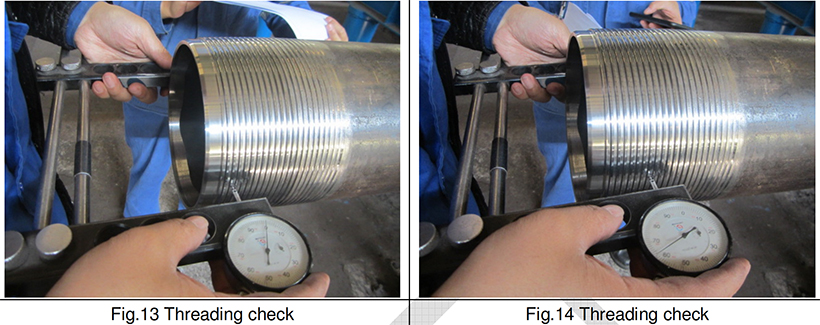

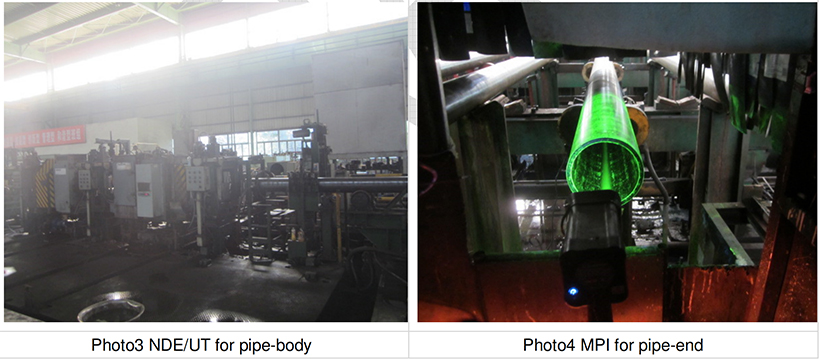

Qualitéitskontroll

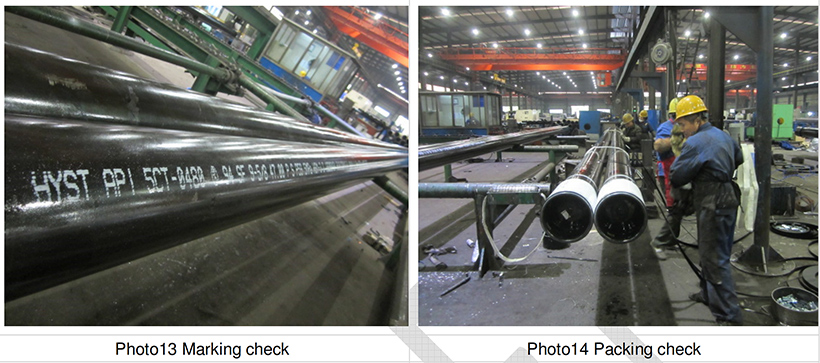

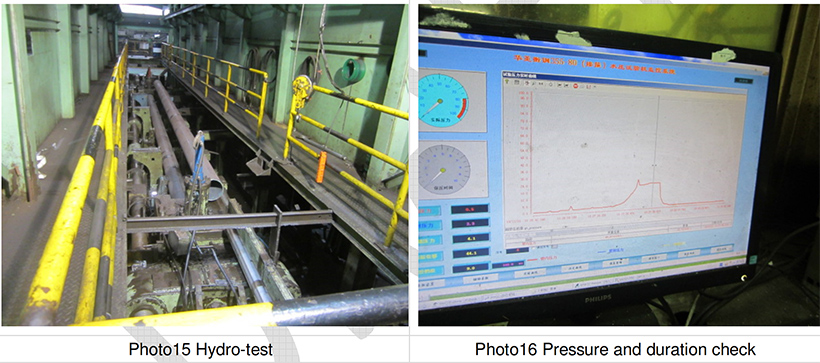

Rohmaterialkontroll, chemesch Analyse, mechaneschen Test, visuell Inspektioun, Spannungstest, Dimensiounskontroll, Biegetest, Ofplattungstest, Schlagtest, DWT-Test, NDT-Test, hydrostateschen Test, Härtetest…..

Markéierung, Lackéierung virun der Liwwerung.

Verpackung & Versand

D'Verpackungsmethod fir Stolrohren ëmfaasst d'Botzen, d'Gruppéieren, d'Verpakung, d'Bündelung, d'Sécherung, d'Etikettéierung, d'Palettéierung (wann néideg), d'Containeriséierung, d'Stauung, d'Versiegelung, den Transport an d'Auspacken. Verschidden Zorte vu Stolrohren a Fittings mat verschiddene Verpackungsmethoden. Dëse komplette Prozess garantéiert, datt d'Stolrohren beim Versand an an optimalem Zoustand op hirer Destinatioun ukommen, prett fir hiren virgesinnten Asaz.

Benotzung & Uwendung

Stolpäifen déngen als Réckgrat vun der moderner Industrie- a Bauingenieurwesen a ënnerstëtzen eng breet Palette vun Uwendungen, déi zur Entwécklung vu Gesellschaften a Wirtschaften weltwäit bäidroen.

D'Stolréier a Fittings, déi mir vu Womic Steel produzéiert hunn, gi wäit verbreet agesat fir Pëtrol-, Gas-, Brennstoff- a Waasserpipelines, Offshore/Onshore, Hafenbauprojeten a Gebaier, Baggeraarbechten, Stolkonstruktiounen, Pfeiler- a Bréckebauprojeten, souwéi Präzisiounsstolréier fir d'Produktioun vu Fërderbandrollen, asw. ...